Indicative metrics — detailed technical & financial data available under NDA.

⚙️ Architect of Circular Ecosystems

Tierras de Montaña – The De-risked Entry Platform for Colombia’s Low-Carbon Cement Transition

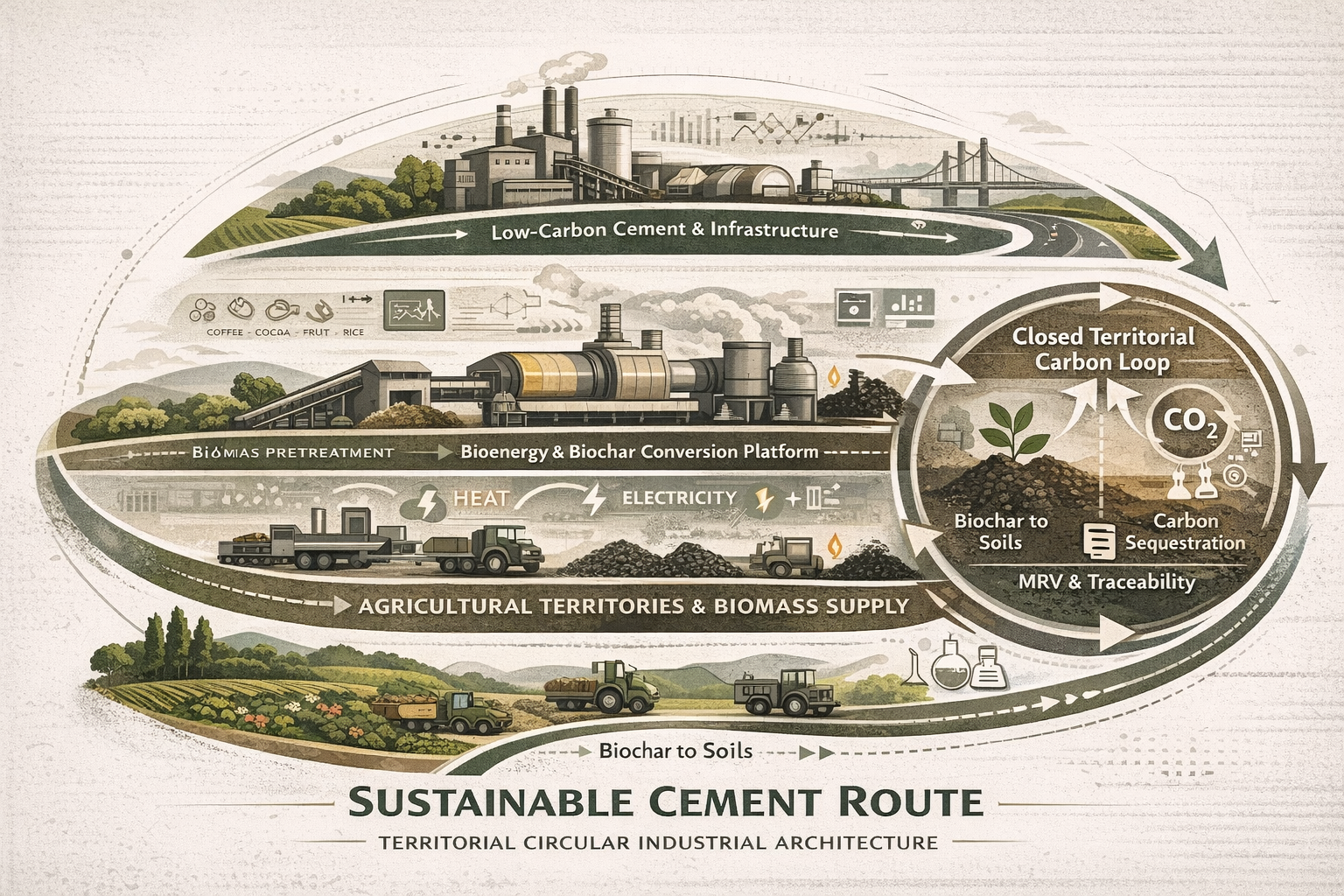

We provide international cement and technology partners with a pre-validated, phased industrial framework—transforming agricultural residues into strategic bioenergy, biochar, and carbon credit streams.

The triple constraint

🏗️ Process

Emissions: Incompressible clinker chemistry demands alternative carbon pathways.

⚡ Fuel Cost Volatility:

High thermal energy dependence creates exposure to fossil fuel markets.

🌍 Territorial Integrity:

Solutions must deliver rural development, soil regeneration, and align with national climate policy.

Our framework is engineered to solve this trilemma.

OUR DE-RISKING BLUEPRINT – The Phased Pathway

A Phased, De-risked Trajectory to Industrial Scale

Our framework breaks down complexity into validated steps, thus reducing technical and investment risks at each stage.

Phase 1: Territorial Bioenergy Pilot

| De-risks: Biomass logistics & tech performance.

Objective: To validate biomass logistics, technological performance, and biochar quality under real-world conditions in Colombia.

Risk reduction outcome: Empirical data for scaling-up decisions.

Phase 2: Industrial Fuel Integration

| De-risks: Operational & economic model at scale.

Objective: Partial replacement of fossil fuels in cement production.

Risk reduction outcome: Proven operational and economic model at industrial scale.

Phase 3: Regional Biochar Complex

| De-risks: Revenue diversification & circular resilience.

Objective: To create a regional hub offering carbon solutions for agriculture and infrastructure.

Outcome in terms of risk reduction: Diversification of revenue streams and industrial resilience.

Execution Anchored in Assets, Not Promises

Institutional Mandate: Direct working relationship with the Ministry of Agriculture, aligning with Colombia’s Strategy 2050.

Social License & Logistics: Operational integration with “Destino de Paz” community networks, ensuring pre-structured biomass offtake.

Technology Validation: R&D partnership with BEST (Austria) for pilot-scale qualification.

Pre-Structured Pipeline: 12+ LOIs from municipalities in Tolima (Chaparral, Planadas) securing biomass supply.

Financial Architecture: MRV frameworks designed for voluntary carbon markets (VERRA) and future compliance markets.

Technical Integration: From Biomass to Circular Value

Our engineered pathway transforms agricultural residues into low-carbon cement production and verifiable carbon assets—creating a closed-loop industrial ecosystem.

Biomass Supply

Agricultural residues sourced from certified rural networks (coffee, rice, palm).

Pretreatment

Drying, grinding & torrefaction to stabilize biomass for thermochemical conversion.

Conversion

Optimized pyrolysis & gasification producing biochar and clean syngas.

Cement Integration

Syngas replaces fossil fuels in precalciner/preheater; raw material drying.

Energy Recovery

Waste Heat Recovery (WHR) systems generate electricity via ORC/steam cycles.

Biochar Application

🔬 Technical Highlights

Basic technical components

Biomass logistics:

Supply chains structured around certified agricultural networks.

Conversion thermochimique :

Optimized pyrolysis and gasification processes for integration into cement plants.

Industrial integration:

Co-treatment with residual heat recovery (RHR) systems.

Carbon tracking, reporting and verification:

Comprehensive measurement, notification and verification for carbon credits and ESG reporting.

Syngas:

Synthesis gas, a mixture of combustible gases produced by gasification.

For Cement Producers & Technology Partners

If you are evaluating biomass co-processing, waste heat recovery, or biochar integration in Latin America, Tierras de Montaña provides the de-risked, pre-structured platform for entry.

A full technical and commercial dossier, including financial modeling and project P&L, is available under mutual NDA.

A full technical and commercial analysis is available under a mutual confidentiality agreement.

Coffee cookie, smile!

You seem to be interested.

Coffee is always better with cookies, we'd like to accompany you ... Is that ok?

Coffee cookie, smile!

You seem to be interested.

Coffee is always better with cookies, we'd like to accompany you ... Is that ok?